- completo

- Nome del prodotto

- parola chiave

- Modello di prodotto

- Riepilogo del prodotto

- Descrizione del prodotto

- Ricerca full-text

| Stato di disponibilità: | |

|---|---|

| Quantità: | |

| Algoritmo avanzato Evidente eliminazione degli angoli storti, arrotondati o sollevati. |

| Statico libero Il problema dell'interferenza elettrostatica da attrito durante il taglio di materiali morbidi e sottili è stato risolto. |

| Alta precisione La taglierina a base piatta della serie VFR è in grado di tagliare piccole stringhe di testo (cerchio minimo 0,8 mm) ed è facile strappare i ritagli. |

| Qualità del bordo pulito e liscio Il righello per reticolo e la corrispondente gestione della forza di taglio garantiscono una qualità dei bordi pulita e liscia. |

| Non è necessario OVERCUT In ogni percorso di taglio, il punto iniziale e quello finale si uniscono tra loro in modo accurato, senza bisogno di impostare alcun OVERCUT. |

| Forza di taglio in 8 fasi, soluzione a più strati Colorare i percorsi di taglio in modo diverso per vari passaggi di forza, impostare la sequenza di elaborazione come sequenza di colori. Ciò è utile per il taglio di supporti con più strati, che richiedono una forza di taglio diversa in strati diversi. |

| Un clic per cancellare la cronologia Pulsante di eliminazione con un clic per il documento attualmente stampato e cancellarlo completamente dalla memoria buffer. |

| Taglio completo/Mezzo taglio/Perforazione/Marcatura, ecc Ogni volta puoi eseguirne uno o entrambi. |

| Uscita diretta DXF È compatibile direttamente con il file DXF senza bisogno di alcuna transizione di formato. |

| Registrazione e taglio segmentati Segni di registrazione multipli in aree segmentate, disponibili per un allineamento degli assi più preciso. Il taglio dei contorni viene eseguito in sequenza in ciascuna area segmentata, migliorando la precisione e il tracciamento dei supporti più pesanti o dei supporti laminati durante il taglio di immagini di grandi dimensioni. |

| Protocollo di stretta di mano Forniamo kit di sviluppo software/SDK da abbinare al software dell'utente, forniamo supporto tecnico e soddisfiamo i requisiti di personalizzazione. |

Specifiche

Modello | VFR1312 | VFR1612F | VFR1325F | ||

Area di taglio non sagomata | 1300x1200 mm | 1520x1200mm | 1300x2500mm | ||

Area di taglio del contorno | 1240x1180mm | 1490x1180mm | 1270x2450mm | ||

Spessore del supporto di taglio | 0,03 mm-1,5 mm | ||||

Supporti applicabili | Mezzi morbidi e di media rigidità | ||||

Metodo per correggere i media | Tavolo a vuoto (pompa a vuoto da 2,2 kW con silenziatore) | ||||

Metodo per alimentare i media | Staffa per nastro trasportatore e supporti in bobina | ||||

Velocità di taglio massima | 600mm/s | ||||

Forza di taglio massima | 600G/5,8N in 8 passaggi | ||||

Impostazione della forza di taglio | Regolabile in ogni 1G | ||||

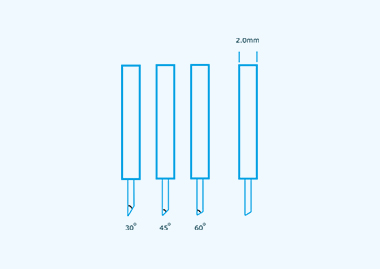

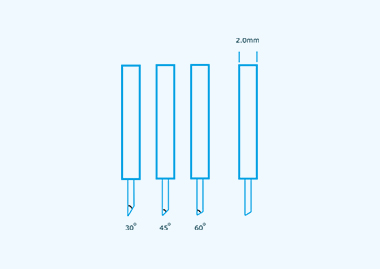

Diametro della lama della taglierina | Φ2,0 mm | ||||

Angoli della lama della taglierina | 30˚/45˚/60˚ | ||||

Taglio di linee tratteggiate | incluso | ||||

Guidare | Servo CA | ||||

Risoluzione meccanica | 0,0125 mm | ||||

Sistema operativo compatibile | Vinci l'8/10/7/XP | ||||

Buffer di memoria | 2 MB | ||||

Software | Driver Windows, Signworkpro, CADtoplotpro | ||||

Linguaggio LCD | inglese/cinese | ||||

Formato del file | HP-GL, PLT | ||||

Porto di serie | USB, RS-232 | ||||

Rilevamento dei contrassegni di registrazione | Telecamera CCD | ||||

Ingresso alimentazione | 220 V/50-60 Hz | ||||

Consumo energetico | Taglierina: 1,5 kW; pompa a vuoto: 2,2 kW | ||||

Strumenti di lavoro | 1 porta lama, 1 porta penna, 10 lame da taglio | ||||

Staffa multimediale | incluso | ||||

Dimensione della macchina (LW) | 1700x1800mm | 2100x1800 mm | 1700x2800mm | ||

Dimensioni dell'imballaggio (LWH) | 1920x1850x1220mm | 2150x1920x1220 mm | 1920x3200x1220mm | ||

Peso | 240 kg/320 kg | 260 kg/340 kg | 680 kg/760 kg | ||

| Algoritmo avanzato Evidente eliminazione degli angoli storti, arrotondati o sollevati. |

| Statico libero Il problema dell'interferenza elettrostatica da attrito durante il taglio di materiali morbidi e sottili è stato risolto. |

| Alta precisione La taglierina a base piatta della serie VFR è in grado di tagliare piccole stringhe di testo (cerchio minimo 0,8 mm) ed è facile strappare i ritagli. |

| Qualità del bordo pulito e liscio Il righello per reticolo e la corrispondente gestione della forza di taglio garantiscono una qualità dei bordi pulita e liscia. |

| Non è necessario OVERCUT In ogni percorso di taglio, il punto iniziale e quello finale si uniscono tra loro in modo accurato, senza bisogno di impostare alcun OVERCUT. |

| Forza di taglio in 8 fasi, soluzione a più strati Colorare i percorsi di taglio in modo diverso per vari passaggi di forza, impostare la sequenza di elaborazione come sequenza di colori. Ciò è utile per il taglio di supporti con più strati, che richiedono una forza di taglio diversa in strati diversi. |

| Un clic per cancellare la cronologia Pulsante di eliminazione con un clic per il documento attualmente stampato e cancellarlo completamente dalla memoria buffer. |

| Taglio completo/Mezzo taglio/Perforazione/Marcatura, ecc Ogni volta puoi eseguirne uno o entrambi. |

| Uscita diretta DXF È compatibile direttamente con il file DXF senza bisogno di alcuna transizione di formato. |

| Registrazione e taglio segmentati Segni di registrazione multipli in aree segmentate, disponibili per un allineamento degli assi più preciso. Il taglio dei contorni viene eseguito in sequenza in ciascuna area segmentata, migliorando la precisione e il tracciamento dei supporti più pesanti o dei supporti laminati durante il taglio di immagini di grandi dimensioni. |

| Protocollo di stretta di mano Forniamo kit di sviluppo software/SDK da abbinare al software dell'utente, forniamo supporto tecnico e soddisfiamo i requisiti di personalizzazione. |

Specifiche

Modello | VFR1312 | VFR1612F | VFR1325F | ||

Area di taglio non sagomata | 1300x1200 mm | 1520x1200mm | 1300x2500mm | ||

Area di taglio del contorno | 1240x1180mm | 1490x1180mm | 1270x2450mm | ||

Spessore del supporto di taglio | 0,03 mm-1,5 mm | ||||

Supporti applicabili | Mezzi morbidi e di media rigidità | ||||

Metodo per correggere i media | Tavolo a vuoto (pompa a vuoto da 2,2 kW con silenziatore) | ||||

Metodo per alimentare i media | Staffa per nastro trasportatore e supporti in bobina | ||||

Velocità di taglio massima | 600mm/s | ||||

Forza di taglio massima | 600G/5,8N in 8 passaggi | ||||

Impostazione della forza di taglio | Regolabile in ogni 1G | ||||

Diametro della lama della taglierina | Φ2,0 mm | ||||

Angoli della lama della taglierina | 30˚/45˚/60˚ | ||||

Taglio di linee tratteggiate | incluso | ||||

Guidare | Servo CA | ||||

Risoluzione meccanica | 0,0125 mm | ||||

Sistema operativo compatibile | Vinci l'8/10/7/XP | ||||

Buffer di memoria | 2 MB | ||||

Software | Driver Windows, Signworkpro, CADtoplotpro | ||||

Linguaggio LCD | inglese/cinese | ||||

Formato del file | HP-GL, PLT | ||||

Porto di serie | USB, RS-232 | ||||

Rilevamento dei contrassegni di registrazione | Telecamera CCD | ||||

Ingresso alimentazione | 220 V/50-60 Hz | ||||

Consumo energetico | Taglierina: 1,5 kW; pompa a vuoto: 2,2 kW | ||||

Strumenti di lavoro | 1 porta lama, 1 porta penna, 10 lame da taglio | ||||

Staffa multimediale | incluso | ||||

Dimensione della macchina (LW) | 1700x1800mm | 2100x1800 mm | 1700x2800mm | ||

Dimensioni dell'imballaggio (LWH) | 1920x1850x1220mm | 2150x1920x1220 mm | 1920x3200x1220mm | ||

Peso | 240 kg/320 kg | 260 kg/340 kg | 680 kg/760 kg | ||

| Carrello portautensili avanzato Il carrello portautensili adotta la struttura di un'auto sportiva, l'utilizzo di un motore silenzioso a bobina mobile lo rende surclassare i suoi rivali. Il carrello portautensili è veloce, agile e senza surriscaldamento per un funzionamento continuo a lungo termine. È un carrello portautensili leader nello stesso campo in Cina. |

| Dispositivo di alimentazione a ventosa Sulla trave della taglierina sono installate diverse ventose per aiutare a trascinare il supporto in primo piano nella macchina per una lavorazione conveniente.

|

| Sistema di vuoto Forte flusso d'aria per mantenere il supporto piatto e stretto contro il piano del tavolo in modo che il carrello dell'utensile possa eseguire tagli/tracciature rapidi e accurati. |

| Sistema di trasporto ad alimentazione automatica Il trasportatore è in grado di eseguire tagli/tracciature lunghe e senza interruzioni. Con la combinazione della telecamera CCD, viene eseguito il piazzamento/taglio dei contorni veloce e preciso. |

| Staffa per supporto in bobina orientata È semplice alimentare il supporto con la staffa del supporto, l'utente può impostare la staffa in base alle caratteristiche e alle specifiche del supporto. La staffa migliora la produttività. |

Righello per grattugia Inevitabilmente la superficie del materiale non è livellata da un punto all'altro, il righello viene applicato per misurare la distanza tra la punta della lama e la superficie del materiale e la profondità di taglio viene regolata di conseguenza ogni 0,01 mm dal controller. Quindi la lama si sposta su e giù man mano che la superficie del materiale si sposta per mantenere la stessa profondità di taglio in qualsiasi posizione dei percorsi utensile sull'intera tavola. In breve, il righello per griglia è di fondamentale importanza per una profondità di taglio costante. | |

| Effettuare la compensazione della punta della lama tramite chip Il nostro sistema effettua la compensazione della punta della lama tramite hardware (scheda principale) anziché software, la taglierina funziona con elevata precisione costante, indipendentemente dal tipo di software CAD/CAM applicato. |

| Servomotore/Controllo ad anello chiuso I servo intelligenti garantiscono un'accelerazione fluida, una coppia elevata, operazioni di taglio/tracciatura precise, durata eccellente e produzione in grandi volumi. I servi assicurano che il plotter da taglio funzioni alla massima velocità. Velocità: 600mm/s. |

Rilevamento rapido dei crocini di registro con la telecamera CCD Con il nostro software dedicato, è in grado di generare contorni con un clic ed è facile aggiungere segni di registrazione. La telecamera CCD, utilizzata in combinazione con il relativo software, viene applicata per rilevare i complessi contorni senza fustella in modo rapido ed efficiente. I problemi causati dall'errore di posizione dell'uomo, stampa di scarsa qualità vengono risolti. La telecamera CCD viene utilizzata per un'ampia varietà di media | |

| Recupero automatico dei dati con codice a barre Basta un tocco per trovare il lavoro di taglio tra quelli salvati nella memoria USB eseguendo la scansione del codice a barre stampato, senza bisogno di collegarsi al computer. Più lavori vengono elaborati automaticamente mentre gli errori di produzione vengono eliminati. |

| Compatibilità software leader Leader nello stesso settore, la taglierina piana VFR è in grado di adattarsi all'ultima versione dei più diffusi software CAD/CAM, come AutoCAD, Adobe Illustrator, Coreldraw, Flexisign, Signmaster; Vari software di modelli nel mercato post-vendita automobilistico come 3M™ Pattern and Solutions Center (PSC), Core di LLUMAR e INTEGO sono già compatibili con questo sistema. |

| Spurgo intelligente per operazioni di sovrapposizione più semplici La funzione di spurgo intelligente semplifica le operazioni di sovrapposizione per gli installatori, questa funzione è molto importante per la realizzazione e l'installazione di segnali/indicatori di grandi dimensioni. |

| Memoria USB/Duplica lavori di taglio offline Gli utenti possono duplicare i lavori di taglio offline, il che è molto più comodo rispetto a farlo collegandosi al PC tramite cavo USB. La funzione di duplicazione dei lavori di taglio con la memoria USB è una tecnologia leader sviluppata da noi stessi. Questa caratteristica è importante per una produzione in volumi efficiente. |

| Componenti di qualità Per prestazioni eccezionali e un funzionamento affidabile a lungo termine, utilizziamo solo componenti di marca di livello mondiale come la cinghia BANDO, il cuscinetto NMB, le guide Ultra-silenziose prodotte da WON Korea, ecc. |

| Un clic per caricare il driver di stampa Ottimizzato il processo di caricamento del driver di stampa con un clic. L'utente può inviare facilmente lavori di taglio tramite qualsiasi CAD dotato di funzionalità stampante. |

| Calibrazione leader La tecnologia leader del settore viene applicata per calibrare la perpendicolare tra i diversi assi e il parallelismo tra il binario del portale e il piano del tavolo. |

| Carrello portautensili avanzato Il carrello portautensili adotta la struttura di un'auto sportiva, l'utilizzo di un motore silenzioso a bobina mobile lo rende surclassare i suoi rivali. Il carrello portautensili è veloce, agile e senza surriscaldamento per un funzionamento continuo a lungo termine. È un carrello portautensili leader nello stesso campo in Cina. |

| Dispositivo di alimentazione a ventosa Sulla trave della taglierina sono installate diverse ventose per aiutare a trascinare il supporto in primo piano nella macchina per una lavorazione conveniente.

|

| Sistema di vuoto Forte flusso d'aria per mantenere il supporto piatto e stretto contro il piano del tavolo in modo che il carrello dell'utensile possa eseguire tagli/tracciature rapidi e accurati. |

| Sistema di trasporto ad alimentazione automatica Il trasportatore è in grado di eseguire tagli/tracciature lunghe e senza interruzioni. Con la combinazione della telecamera CCD, viene eseguito il piazzamento/taglio dei contorni veloce e preciso. |

| Staffa per supporto in bobina orientata È semplice alimentare il supporto con la staffa del supporto, l'utente può impostare la staffa in base alle caratteristiche e alle specifiche del supporto. La staffa migliora la produttività. |

Righello per grattugia Inevitabilmente la superficie del materiale non è livellata da un punto all'altro, il righello viene applicato per misurare la distanza tra la punta della lama e la superficie del materiale e la profondità di taglio viene regolata di conseguenza ogni 0,01 mm dal controller. Quindi la lama si sposta su e giù man mano che la superficie del materiale si sposta per mantenere la stessa profondità di taglio in qualsiasi posizione dei percorsi utensile sull'intera tavola. In breve, il righello per griglia è di fondamentale importanza per una profondità di taglio costante. | |

| Effettuare la compensazione della punta della lama tramite chip Il nostro sistema effettua la compensazione della punta della lama tramite hardware (scheda principale) anziché software, la taglierina funziona con elevata precisione costante, indipendentemente dal tipo di software CAD/CAM applicato. |

| Servomotore/Controllo ad anello chiuso I servo intelligenti garantiscono un'accelerazione fluida, una coppia elevata, operazioni di taglio/tracciatura precise, durata eccellente e produzione in grandi volumi. I servi assicurano che il plotter da taglio funzioni alla massima velocità. Velocità: 600mm/s. |

Rilevamento rapido dei crocini di registro con la telecamera CCD Con il nostro software dedicato, è in grado di generare contorni con un clic ed è facile aggiungere segni di registrazione. La telecamera CCD, utilizzata in combinazione con il relativo software, viene applicata per rilevare i complessi contorni senza fustella in modo rapido ed efficiente. I problemi causati dall'errore di posizione dell'uomo, stampa di scarsa qualità vengono risolti. La telecamera CCD viene utilizzata per un'ampia varietà di media | |

| Recupero automatico dei dati con codice a barre Basta un tocco per trovare il lavoro di taglio tra quelli salvati nella memoria USB eseguendo la scansione del codice a barre stampato, senza bisogno di collegarsi al computer. Più lavori vengono elaborati automaticamente mentre gli errori di produzione vengono eliminati. |

| Compatibilità software leader Leader nello stesso settore, la taglierina piana VFR è in grado di adattarsi all'ultima versione dei più diffusi software CAD/CAM, come AutoCAD, Adobe Illustrator, Coreldraw, Flexisign, Signmaster; Vari software di modelli nel mercato post-vendita automobilistico come 3M™ Pattern and Solutions Center (PSC), Core di LLUMAR e INTEGO sono già compatibili con questo sistema. |

| Spurgo intelligente per operazioni di sovrapposizione più semplici La funzione di spurgo intelligente semplifica le operazioni di sovrapposizione per gli installatori, questa funzione è molto importante per la realizzazione e l'installazione di segnali/indicatori di grandi dimensioni. |

| Memoria USB/Duplica lavori di taglio offline Gli utenti possono duplicare i lavori di taglio offline, il che è molto più comodo rispetto a farlo collegandosi al PC tramite cavo USB. La funzione di duplicazione dei lavori di taglio con la memoria USB è una tecnologia leader sviluppata da noi stessi. Questa caratteristica è importante per una produzione in volumi efficiente. |

| Componenti di qualità Per prestazioni eccezionali e un funzionamento affidabile a lungo termine, utilizziamo solo componenti di marca di livello mondiale come la cinghia BANDO, il cuscinetto NMB, le guide Ultra-silenziose prodotte da WON Korea, ecc. |

| Un clic per caricare il driver di stampa Ottimizzato il processo di caricamento del driver di stampa con un clic. L'utente può inviare facilmente lavori di taglio tramite qualsiasi CAD dotato di funzionalità stampante. |

| Calibrazione leader La tecnologia leader del settore viene applicata per calibrare la perpendicolare tra i diversi assi e il parallelismo tra il binario del portale e il piano del tavolo. |

| Soffiatore a vuoto. La taglierina a base piana con alimentazione automatica VFR funziona con un soffiatore a vuoto di qualità stabile, che funziona continuamente per più di 24 ore senza problemi di surriscaldamento. |

| Porta lama fine. La lama della taglierina funziona con precisione e non cade durante il taglio di supporti spessi e appiccicosi. |

| Disponibili lame da taglio in serie. Angolo: 30°/Φ 2,0 mm per supporti più spessi o caratteri piccoli Angolo: 60°/Φ2,0 mm per pellicola riflettente Angolo: 45°/Φ2,0 mm per pellicola PPF/PET |

| Soffiatore a vuoto. La taglierina a base piana con alimentazione automatica VFR funziona con un soffiatore a vuoto di qualità stabile, che funziona continuamente per più di 24 ore senza problemi di surriscaldamento. |

| Porta lama fine. La lama della taglierina funziona con precisione e non cade durante il taglio di supporti spessi e appiccicosi. |

| Disponibili lame da taglio in serie. Angolo: 30°/Φ 2,0 mm per supporti più spessi o caratteri piccoli Angolo: 60°/Φ2,0 mm per pellicola riflettente Angolo: 45°/Φ2,0 mm per pellicola PPF/PET |

Materiali adatti: Pellicole riflettenti, pellicole a trasferimento termico, pellicole protettive per vernice/PPF, rivestimento per veicoli, oscuranti per vetri, adesivi in vinile, vinili a trasferimento termico, adesivi magnetici, gomma resistente alla sabbiatura, pellicole decorative per telefoni cellulari (2D/3D), pellicole a più strati, pellicole per flessibili Circuito, pellicola di vetro, pellicola in PVC con spessore 0,03-0,75 mm, pellicola in PET con spessore 0,03-1,5 mm, carta per biglietti fino a 500 g/m²; È una soluzione efficiente per il taglio di perforazione, il mezzo taglio, la marcatura, ecc.

SCampo adatto: Aftermarket automobilistico, decorazione di veicoli, industria della segnaletica stradale, produttori di insegne, imballaggi, firma di abbigliamento, progettazione di scarpe, progettazione di borse, industria dei compositi, stampa offset, realizzazione di campioni, espositori POP e altro ancora.

Campioni funzionanti

|  |  |

|  |  |

|  |  |

|  |  |

Materiali adatti: Pellicole riflettenti, pellicole a trasferimento termico, pellicole protettive per vernice/PPF, rivestimento per veicoli, oscuranti per vetri, adesivi in vinile, vinili a trasferimento termico, adesivi magnetici, gomma resistente alla sabbiatura, pellicole decorative per telefoni cellulari (2D/3D), pellicole a più strati, pellicole per flessibili Circuito, pellicola di vetro, pellicola in PVC con spessore 0,03-0,75 mm, pellicola in PET con spessore 0,03-1,5 mm, carta per biglietti fino a 500 g/m²; È una soluzione efficiente per il taglio di perforazione, il mezzo taglio, la marcatura, ecc.

SCampo adatto: Aftermarket automobilistico, decorazione di veicoli, industria della segnaletica stradale, produttori di insegne, imballaggi, firma di abbigliamento, progettazione di scarpe, progettazione di borse, industria dei compositi, stampa offset, realizzazione di campioni, espositori POP e altro ancora.

Campioni funzionanti

|  |  |

|  |  |

|  |  |

|  |  |